Finishes and markings

Our finishing workshop

To enable you to see the finished version of your product, we offer various finishes depending on the process and the material used. Our full expertise is given to finishing your parts in our dedicated workshop using qualified painting technicians, high-end products and a colour mixing machine.

Applications

- Visible parts for marketing presentations.

- Mechanically stronger parts.

- Electromagnetic shielding.

- Production parts.

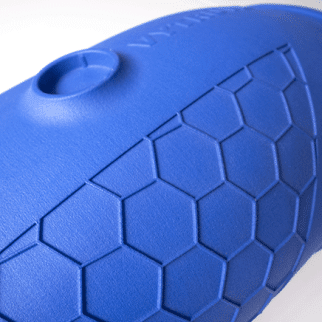

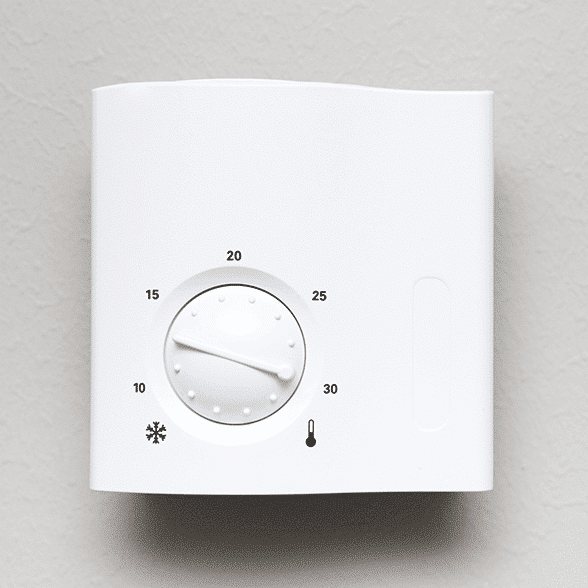

Paint and surface appearance

Our wide range of paint systems means you can have parts in the colour of your choice.

- We also propose metallic paints as well as all car and motorcycle bodywork colours.

- Special-effect paints can be produced on request.

We can offer a variety of surface finishes :

- Satin, matt, smooth, fine grain, medium grain, soft varnish, etc.

- Gloss polished: nickel, brushed nickel for a stainless steel appearance, copper.

- Matt: artistic or technical copper, nickel or technical black nickel.

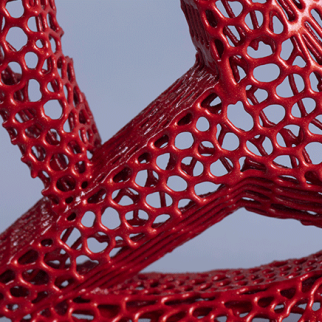

Colouring parts

Our DyeMansion colouring equipment produces a perfect finish.

- Catalogue of 16 standard colours.

- 180 RAL colours to bring life to your projects.

- Specific colours on request.

- Mechanical functions protected.

Finishes catalogue

Download our finishes catalogueSealing or impregnation coatings

To seal them against fluid ingress or high pressure, the application of a sealant coating or an impregnation is recommended. Once treated, the printed parts are totally hermetically sealed and resist high pressures and aggressive fluids such as fuels or solvents.

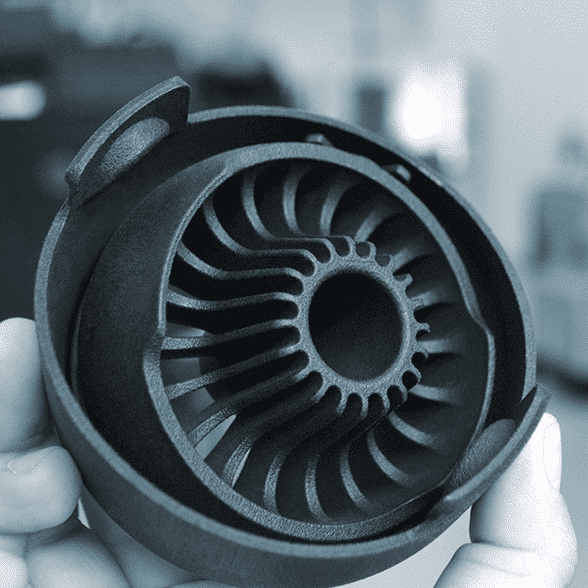

Vibratory finishing

Vibratory finishing is often used as an alternative to manual finishing for 3D printed parts, as it produces smoother and more uniform surfaces in a shorter time.

It can also be used to improve resistance to fatigue and to corrosion on 3D printed parts by eliminating micro-fissures and stress points.

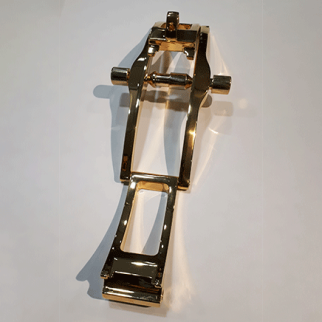

Metal coating

Metal coating is often used to improve the physical and aesthetic properties of parts by creating a gloss metal finish and rendering them resistant to corrosion.

3D printed parts may exhibit a rough or granular appearance.

Metal coating produces a smooth, gloss finish that can be useful in aesthetic applications to produce a metal appearance on a plastic part, or to improve the mechanical properties of the part (impact resistance, temperature withstand, protection against abrasion, improved de-moulding, improved surface finish, etc.).

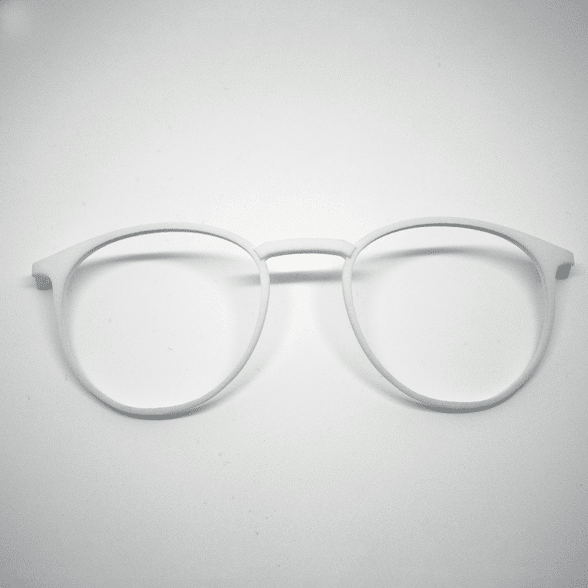

Parts marking

- Laser marking, which creates a permanent, precise engraving on the part surface.

- Pad printing, which enables high-quality printing on curved or uneven surfaces.

- Dry transfer, which enables photo-quality printing on a wide range of materials to integrate your logo or technical information..

- Lastly, screen printing, which is ideal for projects requiring high wear resistance..