SLS HD 3D printing.

Read more

Rapidity

Precision

Mechanical strength

Manufacturing process

Methodology

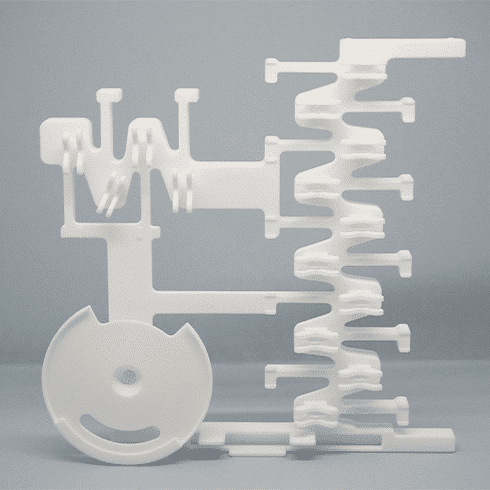

With powder sintering, your parts are created by layering molten polymer under the action of a CO² laser, enabling the manufacture of highly complex geometries. In a pre-heated chamber, a polyamide (nylon) powder is deposited on a manufacturing platform. An infrared laser beam melts the powder only in the areas corresponding to the part. As the powder solidifies again, the upper stratum attaches to the lower layer, gradually forming the part.

Our strengths

- High productivity

- Optimized costs and lead times

- Operational flexibility: able to create a specific process on demand

- ISO 9001 – EN 9100 certification

Applications

A high-precision rapid prototyping tool.

- The resulting prototypes feature enhanced resolution thanks to thinner layers and a finer laser spot.

- Accuracy and detail rendering are considerably enhanced.

- Ideal for small production runs and the most demanding creations.

Our equipment

- 2 x EOSINT® P110 Formiga capacity: 200 x 250 x 330 mm

Our materials

- PA 2200 HD

-

PA 2200 HD

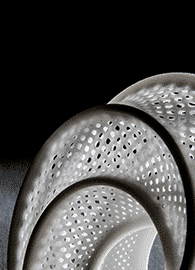

PA 2200 HD is a thermoplastic commonly used in industry. It is a high-performance engineering plastic, specially designed for the production of robust, wear-resistant parts.

Download the data sheetProperties- Color: white

- Ideal for clips

Advantages- Flexible

- Very fine, detailed parts

Limitations- Small parts

Accuracy- Minimum wall thickness = 0.4 mm

- Wall thickness = 0.7mm

- Layer thickness = 60/100 µ

Comparison of 3D technologies and plastics

Do you know which material is the most suitable for your high definition 3D printing project?

View our comparison or why not get in touch with us.