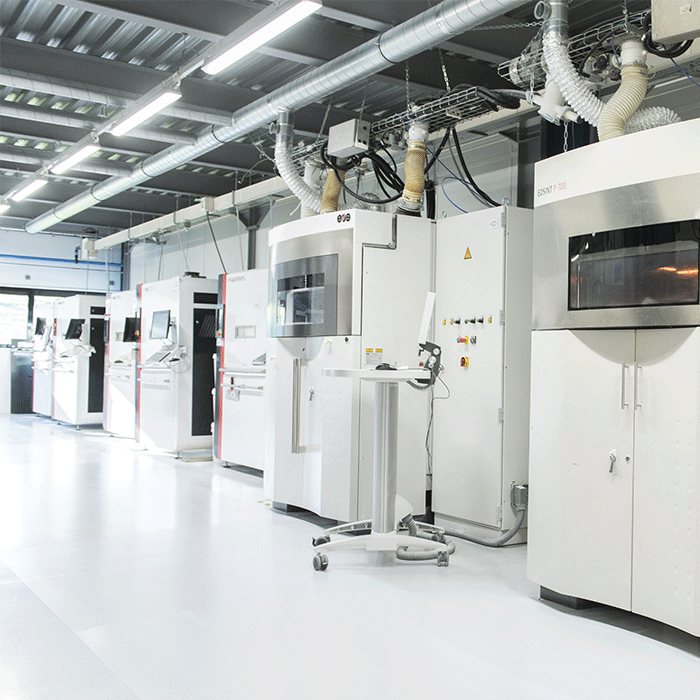

3D printing at the centre of all your innovation

Advising you on the most appropriate technology choices

- 01 3D engineering

- 02 Rapid prototyping

- 03 Tools

- 04 Serial production

3D engineering

Since it was set up in 1991, the INITIAL design office has become a benchmark for product development. Our team of engineers and design engineers possess extensive expertise in designing products, combined with an innovative approach.

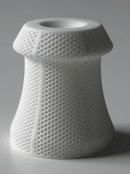

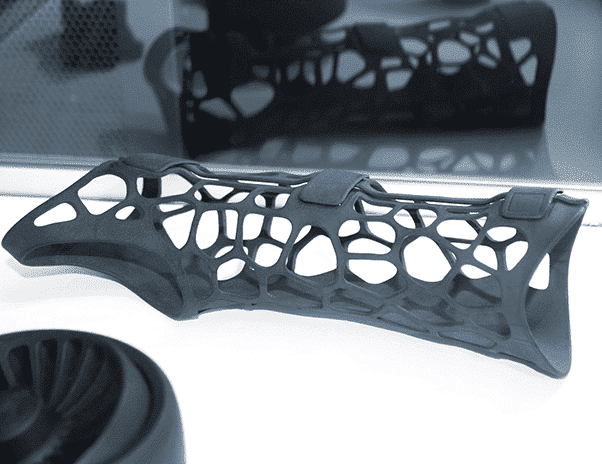

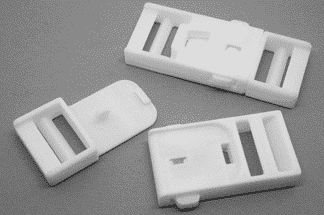

Rapid prototyping

From the seamless integration of your needs to delivering appropriate and original solutions, INITIAL stands out by developing rapid, innovative, plastic and metal prototyping solutions alongside a singular production capacity.

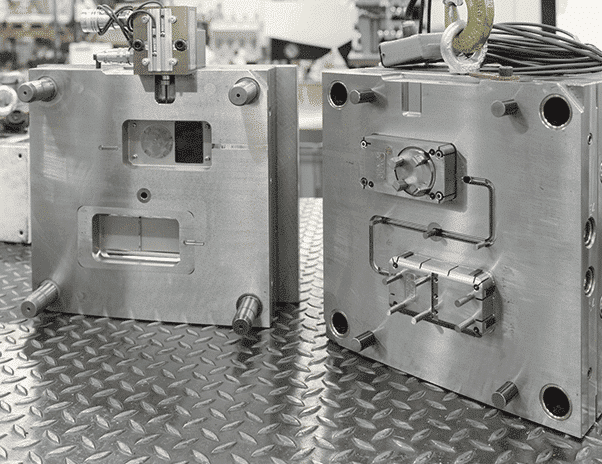

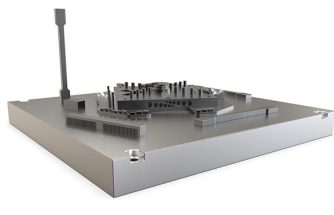

Tools

We design your moulds in our dedicated design office. Through our range of tooling technologies, we offer custom solutions to build your production-grade prototypes or production parts.

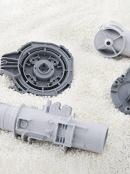

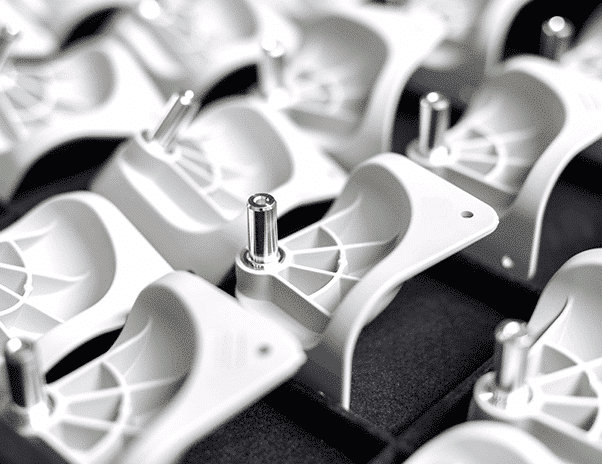

Serial production

Technical thermoplastics are transformed in conventional conditions for serial production parts and appropriate quality control is implemented as per your requirements. The flexibility of our structure makes it possible to have short production runs and reduced turnaround times.

Exclusive divisions dedicated to your innovations

Your challenges, our responses

Each challenge is met with our technology solutions alongside our service and support capacities, to respond to the most demanding applications. Take a look at our latest achievements.

All our achievements

Do you have a project?

Our team of professionals will advise and guide you

towards the best choices for all your projects.

The agile manufacturer and producer of your 3D designs

Welcome to a company where the key words are expertise, innovation and customer satisfaction!

Our aim is to deliver a global turnkey solution offering expertise and competitiveness.

This is the challenge that our teams face every day.

Our employees trained in the latest technologies combine their skills to serve you.

Our news

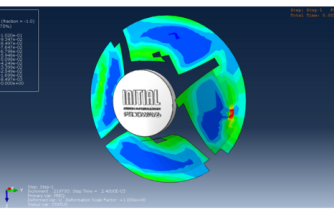

Discover Abaqus: Our new asset in digital simulation

Read more

Testing and characterising metal 3D printing

Testing and characterising metal 3D printing using “test pieces”

Read more

France relaunch industry

A grant obtained for the “Futur3D” R&D programme, as part of the “Relance Industrie” plan.

Read more

PA11, a new 100% bio-based material

A 100% bio-based polymer produced from castor oil is enhancing our plastic 3D printing offering.

Read more