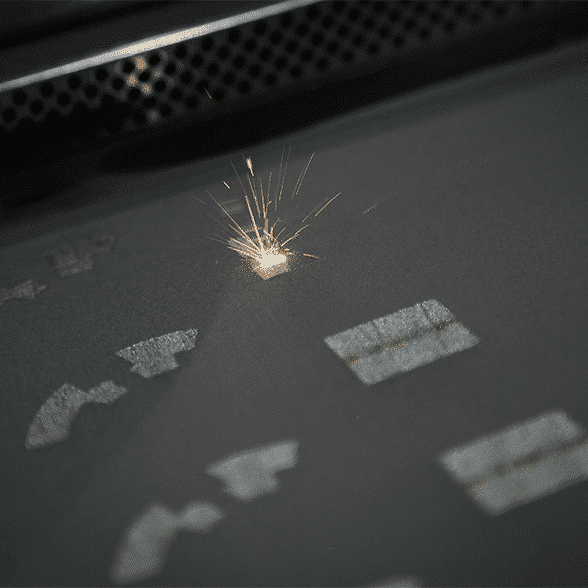

We use our range of machines to process materials in the form of powders, which are all of a uniform and consistent quality.

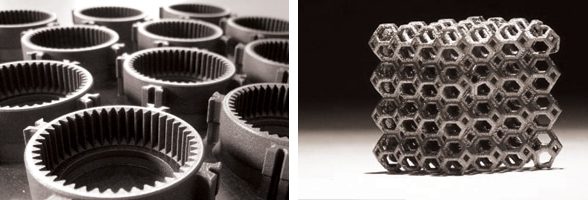

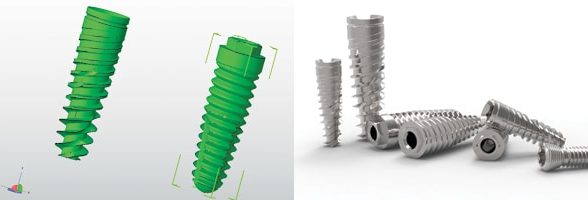

We choose our suppliers with rigour and attention to detail and use the materials with dedicated and qualified machine parameters.

Our aim is to be able to produce and reproduce your parts in the long term.