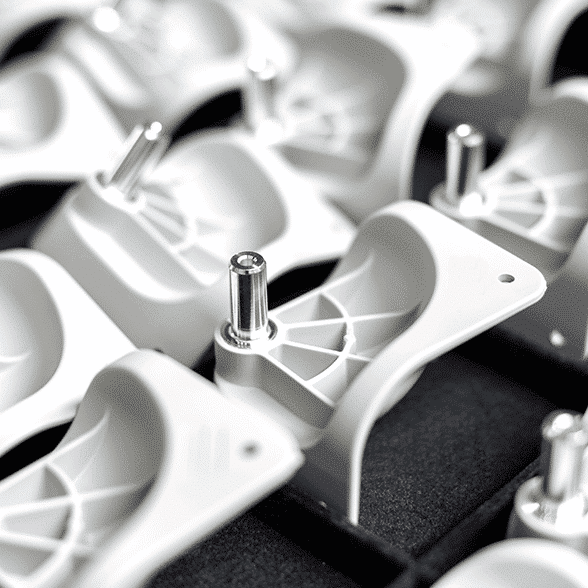

Thermoplastic injection moulding

Production of your plastic parts

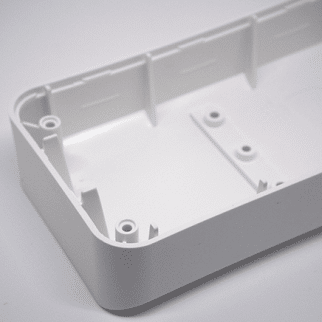

Thermoplastics are processed under conventional conditions for the production of mass-produced parts, and quality control tailored to your requirements is implemented. Our flexible structure enables us to produce short runs and short lead times.

Our assets for the production of your plastic parts

- Experience in the use of technical materials.

- Production control for series production: we draw up control ranges in agreement with your quality department to monitor manufacture.

- Traceability guaranteed by batch number identification.

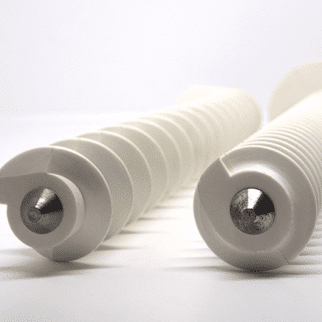

We also make overmoulded parts:

- plastic + plastic (soft)

- metal + plastic insert

Finishes

- Decoration of parts by screen or pad printing: please consult us on a case-by-case basis.

Production

Parts injected in 2022

Injection molding machines

Machinery

Expertise

Complete division

Complete division

We have over 20 years’ experience in thermoplastic injection molding.

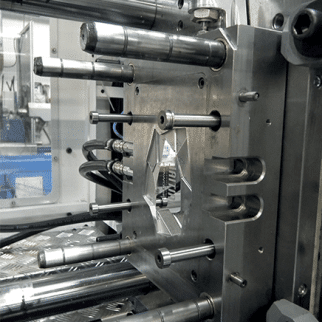

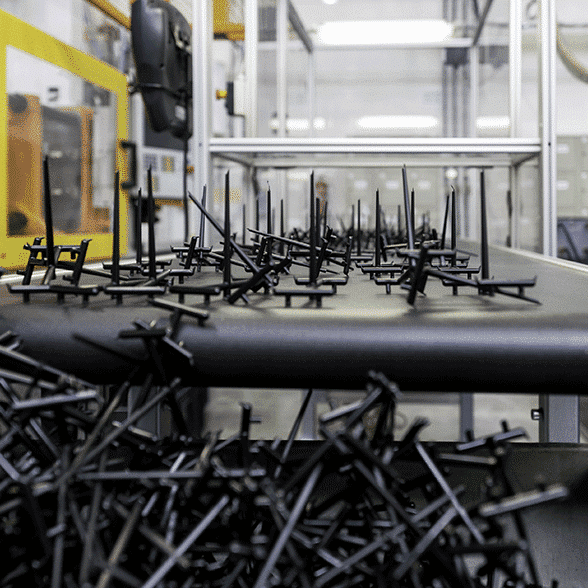

- Flexible machinery comprising 6 injection moulding machines of 22 T, 50 T, 100 T and 150 T.

- Water and oil temperature controllers.

- Material dryer.

- Robots and sprue picker.

A complete centre comprising around twenty people:

- A tooling design office.

- A mechanical workshop.

- An injection workshop.

- A quality control department.

- For each project, you will be in contact with a project manager who will be your sole point of contact.

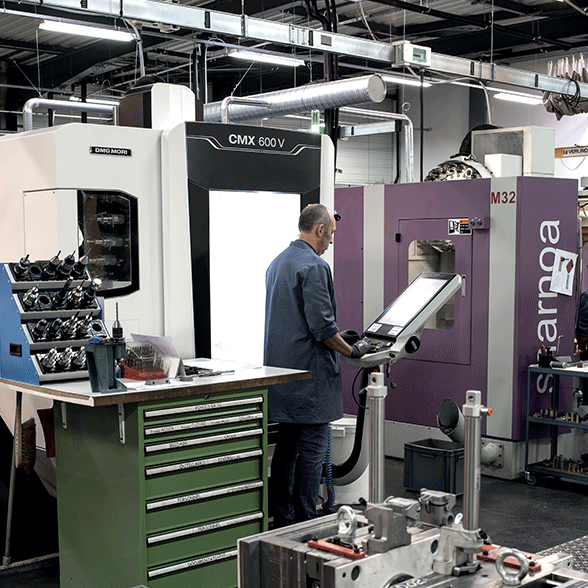

Mechanical workshop

The workshop specialises in small and medium series moulds corresponding to the injection workshop presses.

- 2 CAD/CAM workstations equipped with Work NC.

- 1 radial drilling machine.

- 5 machining centres (HSM, 3-axis and 5-axis).

- 1 EDM sinking machine.

- 2 wire cutters.

- 1 surface grinding machine.

- 1 polishing station.

Methodology

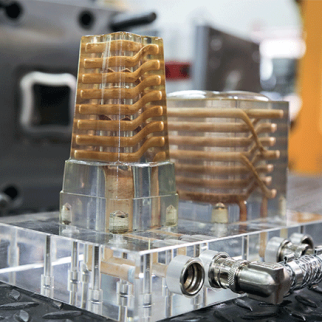

Following a meeting to launch the project, we carry out a tooling study based on the 3D file of your part:

- CAD/CAM generation of toolpaths and electrodes.

- Machining of cavities.

- Polishing of cavities or specific graining.

- Mould adjustment and assembly.

- Injection testing and tooling adjustment (MAP).