Metrology and tomography

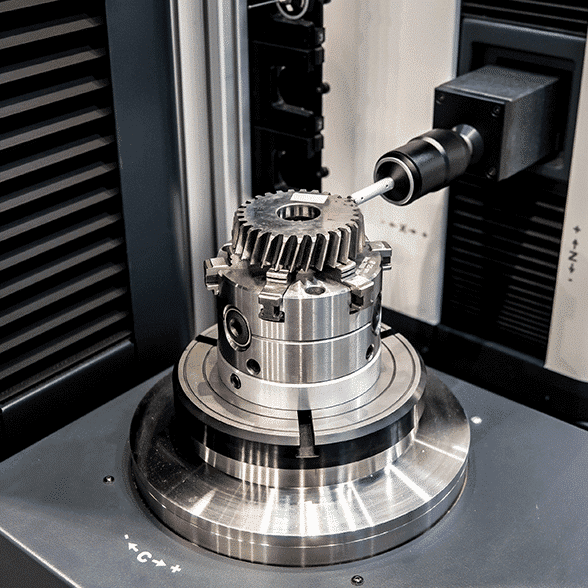

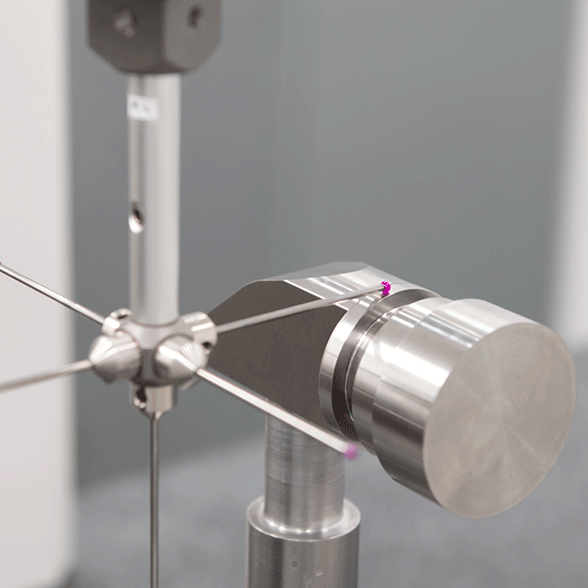

Metrology

2D and 3D dimensional measurements

We adapt our measuring equipment to your types of parts and your specific issues.

The metrology of a part consists in taking reliable, precise measurements of its geometrical and dimensional properties, such as its length, width, height, diameter, roughness, etc.

- It serves to check if the part complies with the required specifications and to detect any errors or production defects.

- We propose 2D and 3D dimensional measurements or geometric analyses using conventional or optical resources.

Technical expertise

Analyse and inspect your parts with precision

Measurements are made according to rigorous procedures, in accordance with standards and tolerances defined for the part.

Methodology

- Three-dimensional measurement devices and optical measurement machines.

- All measurements are made in air-conditioned rooms, on metrology quality machines calibrated using national standards.

Deliverables

On completion of the measurements and depending on your needs, we deliver:

- a certified inspection report,

- a capability analysis.

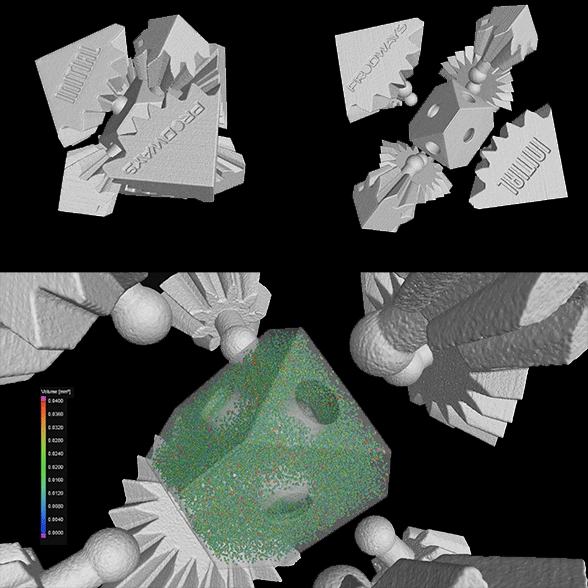

X-rays

View the invisible with tomography

Industrial tomography is based on the use of X-rays and the only non-destructive testing technology that enables us to see into the very core of the material.

Whether for very basic or very complex parts, an accurate 3D model can be exported to measure internal and external geometries.

Tomography data contain all the geometrical data for the part and can be used to complete various types of analysis:

- Porosity analysis

- Wall thickness analysis

- Comparison of a scanned part against its CAD file

- To complete reverse engineering.

Complex parts

Download the case study

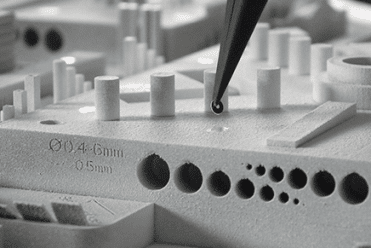

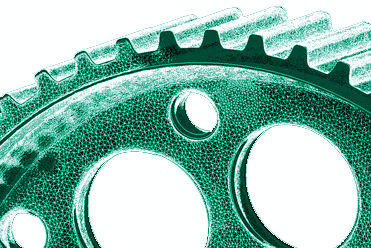

3D Scanning

We use our 3D optical scanner to capture the geometrical form of your parts and transform the data into a 3D file.

Find out more

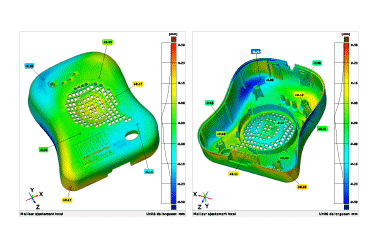

3D Scan inspection

Analysis of dimensional and/or shape differences between the nominal file and the scanned part.

Find out more

Reverse engineering

Transform the data from a 3D scan into a file fully compatible with your CAD software.

Find out more