Industry

INDUSTRIAL 3D PRINTING FOR YOUR PRODUCTS, FOR YOUR FACTORIES

Industrial 3D printing is a key factor in developing your products and will save precious time in the design process.

It is also an excellent means to differentiate your activity, as it is perfectly capable of serial production of plastic or metal parts.

Your parts can be totally customised, scalable and enable zero inventory, as they can be produced on demand.

Furthermore, plastic and metal 3D printing is ideal for workshop equipment: inspection holders, maintenance or assembly holders, etc.

- The special machines incorporate many polyamide components.

- Production of parts via metal melts with integrated cooling channels.

- Shorter lead times to produce complex parts.

WE DELIVER INNOVATION TO IMPROVE YOUR SPEED, EFFICIENCY AND COSTS

Ever-harsher global competition with an increasing number of remote or low-cost competitors should drive you to be more relevant and create more added value in your products.

We conduct over 150 product analyses every year. Our team offers a very varied experience and will apply itself to all your requirements to achieve the desired objective.

We are fully adept in using the most advanced CAD software to ensure a result to match your needs:

- PTC creo

- ABAQUS

- CATIA

- Solidworks

We use all technologies to manufacture your prototypes or serial products.

Our solutions are adaptive, from single parts or small series produced using additive technologies, to intermediate series produced using vacuum casting, right up to mass production using injection moulding.

A custom response to very varied requirements in industrial 3D printing.

From machined metal moulds to injection-moulded parts,, we exhibit rare know-how in a brand new factory, fitted out with the latest equipment.

3-axis or 5-axis machining, HSM, erosion, electric presses equipped with robots and more, all such equipment enables high-quality production for your series of plastic products.

Contactless digitisation enables considerable time savings in the design, inspection, and finalisation of your parts.

3D scanning is wholly essential to the Design Office and will enable you to make contactless inspections of many different parts such as complex forms, or deformable and flexible parts that are hard to access.

It is an ideal way to duplicate old shapes or to measure the footprint of a damaged tool, or where a digital description does not exist.

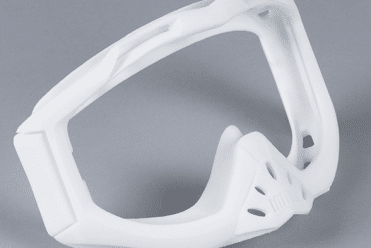

A 3D printed flexible mask

Capping parts made by additive manufacturing