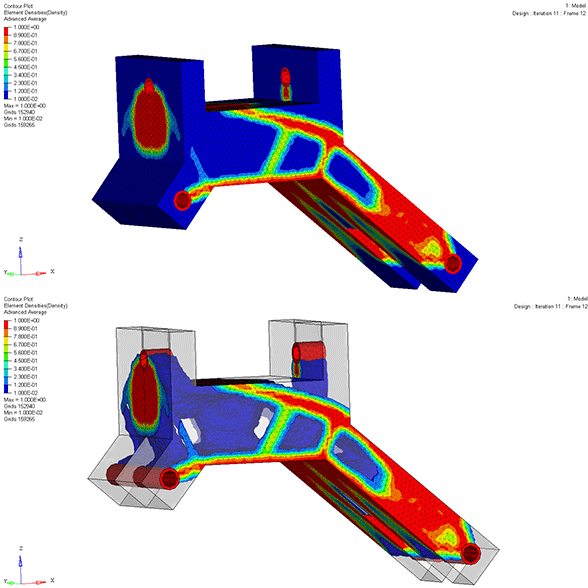

Topology optimisation

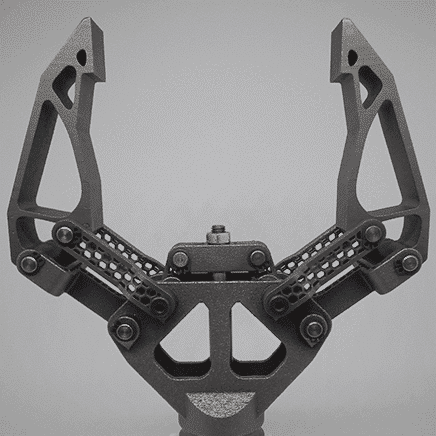

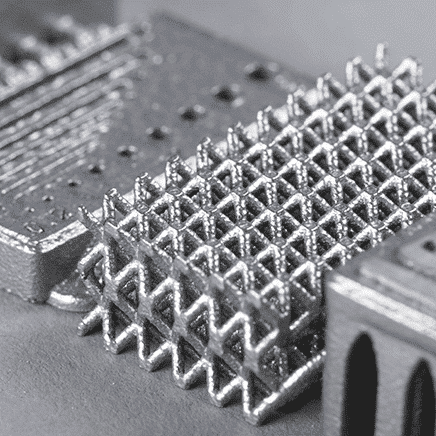

Lightweight structures method

Design using minimum materials

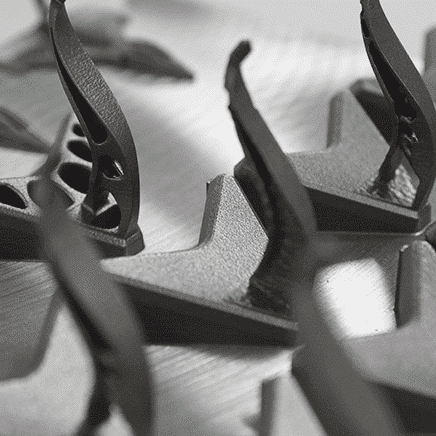

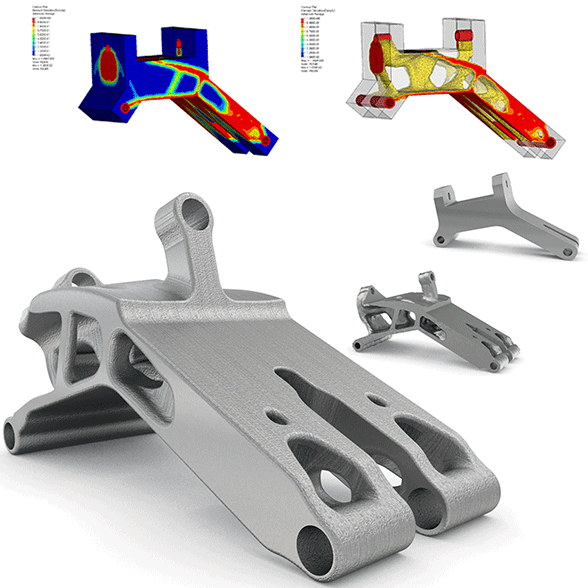

Topology optimisation is a cutting-edge technique which enables material to be distributed over a part, leaving only the volume that is strictly necessary while adhering to load and strength constraints.

Our expertise and our fleet of machines enable us to disrupt “traditional” parts design by using suitable lightweight structure methods such as lattice structures and topology optimisation, depending on the issues you need to resolve.

Based on your specifications, we can design or re-design your parts and sub-assemblies for comprehensive optimisation.

Optimum geometries

We offer optimum geometries to ensure an ideal match with your operating requirements.

Benefits of 3D printing

Topology optimisation is possible through the freedom of forms and geometries offered by 3D printing technologies.

Technical expertise

Our strengths

Our skills and know-how ensure we have mastered all stages of the optimisation process, right up to finalising the physical model.

METHODOLOGY

- Examination of your specifications (boundary conditions, forces, dimensions, etc.).

- Provision of data required for optimisation calculations.

- Analysis of results:

(ABAQUS) - Optimisation report.

BENEFITS

- Considerable weight savings.

- Fewer product references required in stock.

- Custom quantities for stock management.

- No tools to be made.

- Eco-design, material savings.