3D printing in the service of Art

For a new object DNA

The alarm was sounded by the Legal Director of the Société des Auteurs dans les Arts Graphiques et Plastiques (ADAGP), Thierry Maillard.

This rights management society, entrusted with ensuring the defence and recognition of works, says that it is deeply concerned about the accessibility of processes and the infinite possibilities for unauthorised reproduction that these now offer.

Emerging in the first half of the 1980s, additive manufacturing of an object consists of printing it using successive layers of a material, on the basis of a 3D file.

Originally used by industry to produce prototypes, it has now captured a broader audience.

It is also accompanied by a clear improvement in the available tools and the development of companies specialising in modelling of objects and online 3D printing services.

Thanks to 3D scanner technology, the object produced may be extremely faithful to the original.

Sculptors and designers are especially concerned, highlights Thierry Maillard.

“Painters are too,”

he adds.

Before recalling, by way of an example, the technology developed by Fujifilm and used by the Van Gogh Museum to create high-definition 3D reproductions of some of the artist’s works for collectors.

“Custom 3D printing opens up new creative channels for artists, but we want to regulate production in order to minimise abuse – fakes and counterfeiting.”

A signature inscribed in the material

The preliminary documents talk about a practical and educational document for use as a reference by everyone.

Its aim is to provide a reminder of the applicable rules in intellectual property legislation, propose solutions for adhering to them and defining commitments intended to prevent abuse (respect for copyright, traceability, etc.).

An assignment was officially launched in July 2017 by the Conseil Supérieur de la Propriété Littéraire et Artistique (CSPLA), a consultative body responsible for making recommendations to the Ministry of Culture.

It was handed over to the Councillor of State, Olivier Japiot, whose report was published last December.

Catherine Gorgé, Secretary-General of the Prodways Group, specialising in 3D printers, and Director of the division dedicated to creation, has kept an eye on the ADAGP’s demands and ensured that the latter’s requirements can be applied in practice.

Prodways examined what was technically feasible in order to ensure the traceability of an original piece.

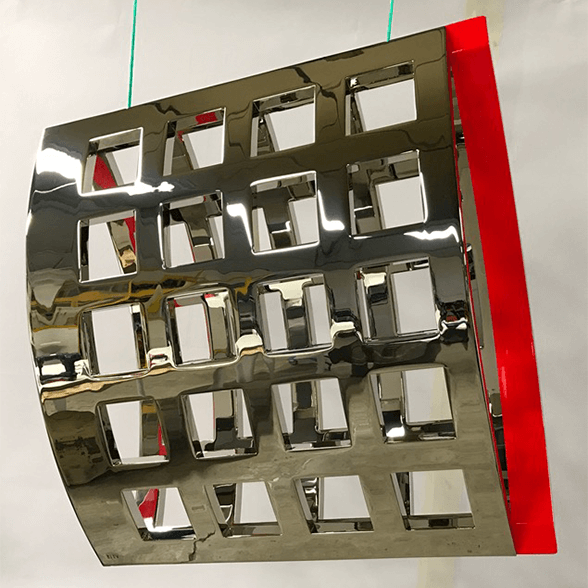

A work, the only one in the world

Made using bespoke 3D printing and with an ID inscribed directly in the materialIts creator, the Brazilian artist Jaildo Marinho compares this marker to “a kind of DNA” proving the authenticity of this sculpture produced by the Prodways Group. This solution, which can only be read by X-rays, is one of many suggestions, but it represents a promising start in the effort to reassure creators.