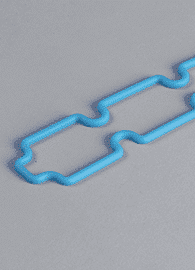

Vacuum casting

Read more

Colours

Small series

Variety of materials

Manufacturing process

Methodology

After creating a master (or model) in SLA stereolithography, a silicone mold is made. The impression left by the master in the mold is filled with polyurethane resin using a vacuum casting machine. The vacuum created in this machine prevents the presence of large quantities of bubbles in the material, which could weaken the part. The service life of a mold can range from 10 to 25 parts, depending on the complexity of its geometry and the type of resin used.

Applications

- Prototypes for mechanical, thermal or aesthetic validation.

- Pre-series for market testing with your customers.

- Pre-series for product certification.

- Small series for marketing.

- Overmolding of specific inserts in all materials.

Our strengths

- Possibility of overmolding and adding inserts.

- Numerous finishes available for a standard or high-end look: metallization or objet d’art/luxury.

- Part dimensions: 600 x 600 mm, maximum 2kg.

- ISO 9001 – EN 9100 certified.

- Certified materials: ROHS – USP 6 – REACH – UL94 – FAR25.

Our equipment

- 1 UGM® 700 machine – cap. 800 x 700 x 700.

- 3 UGM® 400 machines – cap. 400 x 400 x 400.

- 4 ovens.

Vast materials catalogue for your parts

- Our resins

-

Our resins

Polyurethane, epoxy and silicone resins enable you to produce your parts close to the right material. Discover how to produce small series quickly and economically.

Download the comparison chartProperties- PP type, ABS type, filled…

- Rigid, flexible, mixed parts

- Colored, transparent parts,

Advantages- Small batches (approx. 20 pcs.)

- Can be threaded, overmolded,

- Resistant to °C/shock.

Limitations- Tolerances on large parts.

Accuracy- Minimum wall thickness: 0.5mm

Do you have a project?

Do you know which materials or technologies are most suited to your project?

View our comparison or why not get in touch with us.