3D printing for the INSA Racing Team!

[YOUR CHALLENGES//OUR CREATIONS]

3D printing in the service of performance

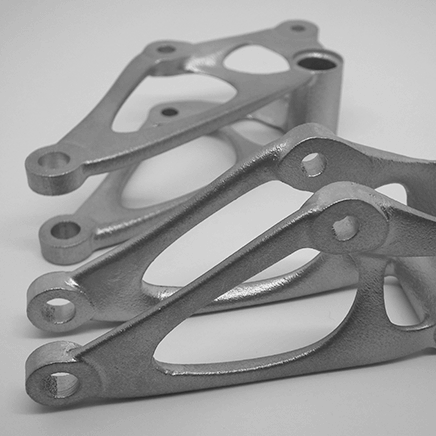

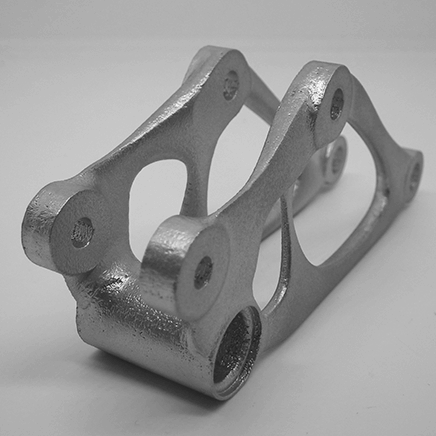

4 rockers were produced by metal 3D printing as part of the vehicle’s suspension.

Created in 2019, the INSA Racing Team by Mécasport is the INSA Lyon’s Formula Student team.

- The project involves around thirty enthusiastic students, whose aim is to design, produce and test a racing vehicle.

- Four mounting parts for the vehicle’s suspension were produced using metal 3D printing technology.

- These parts are key components in the vehicle’s suspension.

- Aluminium AlSi10Mg ensures robustness and hardness thanks to its combination of silica and magnesium.

Technological partnership

Made from aluminium ALSi10Mg by laser sintering, these are vital components of the suspension and shock absorption system, as they transmit movements and forces from the wheel to the shock absorber.

The design of the vehicle’s airbox is remarkable, as part of it was also produced by 3D printing

Part of the vehicle’s airbox was also produced by 3D printing using powder sintering. Production using aluminium-filled polyamide powder.

- This production method ensures that the part is highly resistant to impacts and vibration, as well as to pressure variations that may occur when air is drawn into the engine.

- Thanks to this technique, the airbox will be able to maintain its form and functionality even in extreme conditions, including high temperatures and intense stresses.