3D scanning for a unique project: the creation of an exceptional motorcycle

A motorcycle driven by a promise

When Bruno set out to complete the motorcycle that his friend Jean-Louis had started before he passed away, it was no mere mechanical project. This project is a tribute. Jean-Louis, a former sidecar champion and master craftsman of competition exhausts, dreamed of assembling a Norvin: a hybrid model combining a Norton Wideline Featherbed frame and a Vincent engine, highly coveted by enthusiasts.

3D Scanning as a design security solution

Rather than redo what’s already been done, Bruno decided to design a unique, uncluttered motorcycle in the café racer spirit. This artisanal challenge led him to collaborate with renowned craftsmen for the custom production of components (sand-bent exhausts, hand-formed aluminum tank, leather saddle, custom shock absorbers). To secure construction and assembly, Bruno called on Initial’s expertise to carry out a 3D scan of the Norton frame and Vincent engine, and to design the new components.

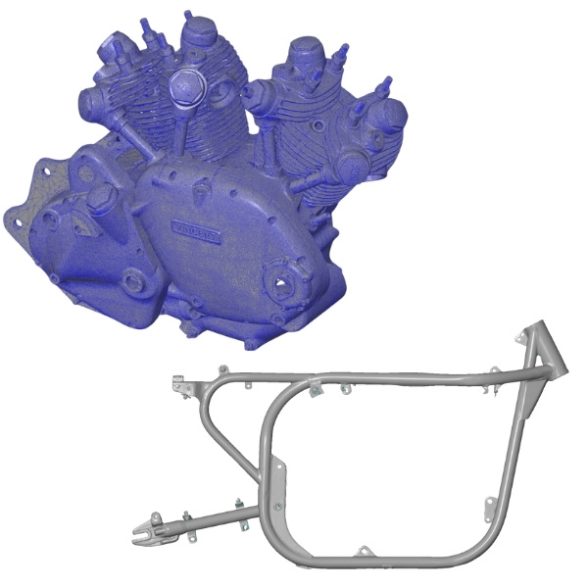

Capture and prepare 3D data for redesign

Our objective was twofold: firstly, to accurately digitize the existing steel frame in order to obtain a faithful 3D model that would serve as inspiration for the design of the final model adapted to the motor used. Then, to enable the new frame to be designed, the Vincent engine also had to be digitized in its entirety and with all its details.

To do this, we used a structured light scanner, suitable for large mechanical parts such as a tubular frame. The 3D scan captured all the geometry – including tubes, gussets, engine mountings and accessory passageways – at a high resolution, ensuring a perfect fit for future components.

A precise digital model

The files generated enabled us to design a new frame, this time in aircraft-grade aluminum, adapted to the dimensions of the Vincent engine but retaining the design of the original Norton frame. Bruno insisted on respecting the cantilever-type swingarm with its double shock absorber typical of the Vincent.

The frame was manufactured on the basis of our design and the resulting drawings, by bending the tubes and welding them by hand. The tank, saddle, engine mounts and exhausts were custom-built around this frame, with a perfect result, the fruit of a combination of digital work and craftsmanship.

This work enabled Bruno to limit the number of adjustments often necessary when building a unique motorcycle by hand. By controlling the dimensions right from the digital stage, he gained in precision, peace of mind and time, while respecting the project’s aesthetic and symbolic specifications.

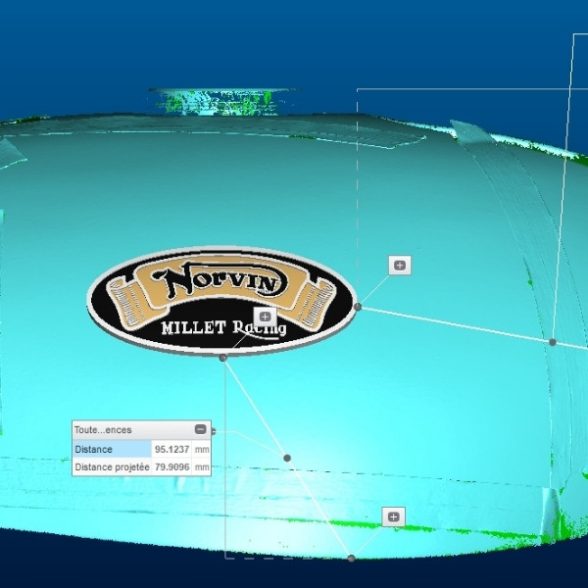

Norton and Vincent of course have their own emblem, and together with Bruno we imagined and created a tank logo for this bike that represents and respects these elements and this history.

A custom tank logo

Once this was done, we scanned the tank, hand-formed by a master boilermaker, and adapted the shape of the tank emblems to fit the tank geometry perfectly.

Finally, once the final digital model had been obtained, we fabricated the right and left emblems using our metal additive manufacturing machines, then entrusted them to an enameller for coloring before placing them on the tank.

Technology at the service of memory

The Norvin project is a perfect illustration of the benefits of 3D scanning for personalization and restoration projects. It makes it possible to optimize each design stage, while respecting the material, history and vision of the designer.

Today, this exceptional motorcycle, which is perfectly functional, is displayed like a work of art. And it’s a source of great pride for our teams to have been able to contribute to this magnificent project, bringing their technical know-how to bear on a human work of art.