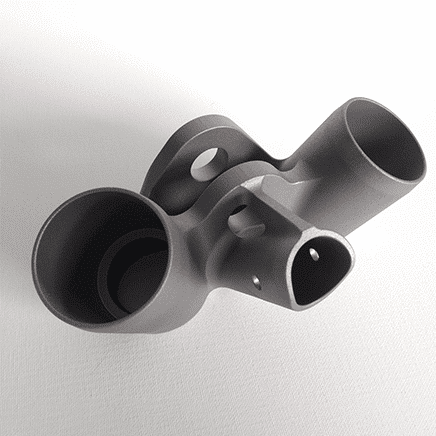

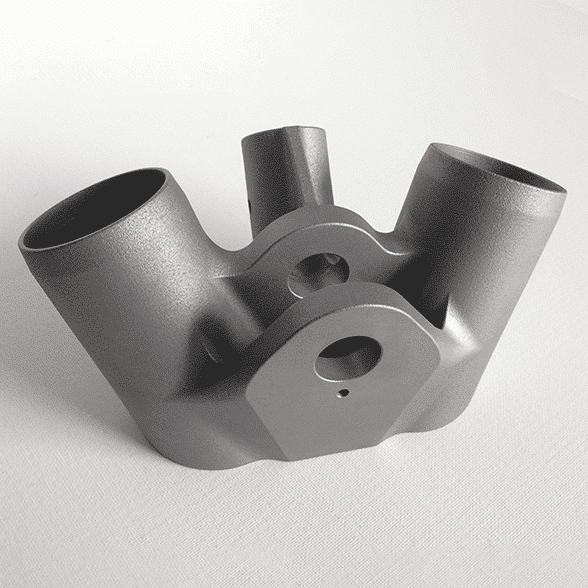

Foil support produced by titanium 3D printing

[YOUR CHALLENGES//OUR CREATIONS]

THE FOIL SUPPORT WAS PRODUCED BY TITANIUM TI64 3D PRINTING FOR A MAXIMUM WEIGHT SAVING.

INITIAL is a major player in the world of metal and plastic Additive Manufacturing. Our production processes for large-scale additive manufacturing apply in numerous sectors, including aviation, as well as the medical and automotive sectors. This part was produced using cutting-edge tools. It showcases our mastery of our production processes.

Metal Sintering, more commonly known as metal 3D printing (ALM), allows complex one-piece parts to be produced.

- DMLS® technology is ideal for prototype or mass produced metal parts: with a weight saving and the use of high-performance materials.

- The foil support was produced by titanium Ti64 3D printing for a maximum weight saving.

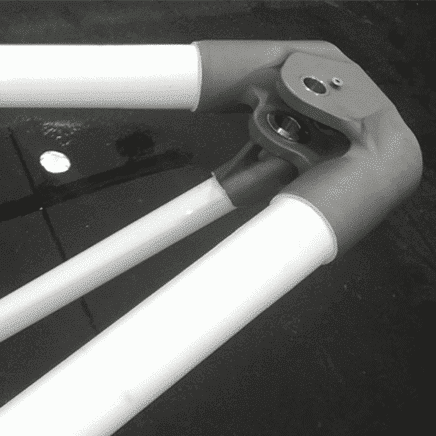

The part was tested under load before being sailed in-house by the teams.

Designed to support the foil system laterally, it allows the boat to “fly”. Covered by aerodynamic fairings, it can withstand 4 to 5 tonnes of traction each time you sail.