3D Molding in the service of innovation

INITIAL & L’Oréal

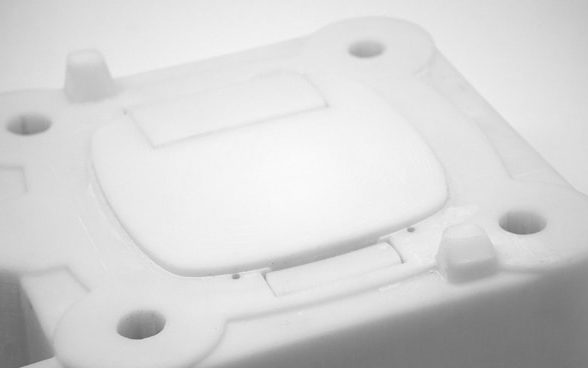

Production of a final material prototype using 3D printed moulds.The rapid market launch of new products poses a constant challenge for meeting consumers’ specific and wide-ranging requirements.

This is a major challenge in the cosmetics industry.

L’Oréal, the global leader in this field, has unique research & innovation expertise.

As a result, 3d molding®, 3D printing combined with injection moulding, is emerging as real opportunity.

Initial and l’Oréal are pooling their know-how to speed up the development of injection moulded parts

L’Oréal is the world’s leading beauty company, with sales of €26 billion in 2017 and close to 7 billion products sold every year, which represents one product per year per person!

INITIAL is the leading French producer of additive-manufactured parts, a Prodways Group subsidiary and, for the past 25 years, has been working to speed up the development of products, by means of its design office’s and manufacturing expertise.

The shared quest for innovation and technical progress fits perfectly into L’Oréal’s programme known as “OPERATIONS 4.0 – DIGITAL TRANSFORMATION OPERATIONS”.

An ambitious mission, in line with increasingly exacting consumer demands.

INITIAL and L’Oréal decided to work together to enable them to produce “final material” parts, in a record time of two weeks and at a low cost, paving the way for accelerated approval and iteration processes for the development of new packaging.

3D printing and thermoplastic injection moulding are finally combined

These two production processes are often presented in opposition, yet they can form a strategic alliance: cutting costs and traditional tooling lead times and paving the way for a new way of working.

The production of so-called “traditional” moulds is subject to production lead times that are no longer compatible with the agility needed to innovate.

This is where 3D printing steps up in terms of responsiveness.

L’Oréal found dedicated resources at INITIAL, with an additive manufacturing site and a thermoplastic injection moulding site.