INITIAL and SPIRGRIPS®, the secrets of the ergonomic grip

3D design and prototyping

SINCE 2014, HE HAS BEEN WORKING WITH INITIAL ON HIS SPIRGRIPS ECONOMIC GRIP CONCEPT.

Our Design Office has helped him develop and perfect this product, which has proved a real hit with both amateur and professional cyclists.

Take a look behind the scenes at the design of these innovative grips.

An exclusive design

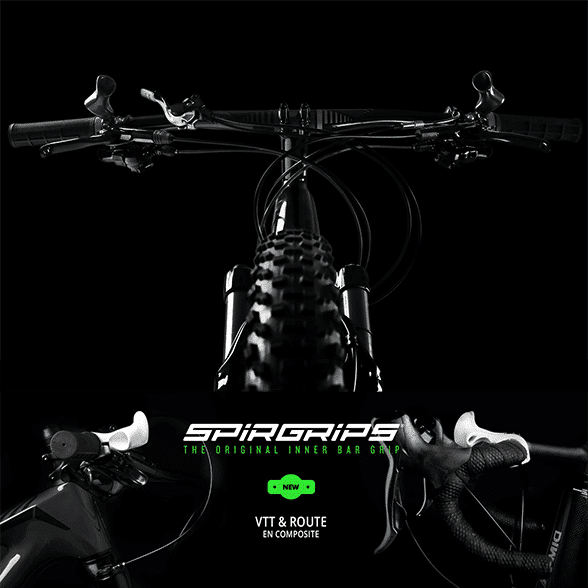

These inner bar grips are attached to the handlebars, within easy reach, and allow you to enjoy a comfortable position optimising both joint support and muscular performance.

A patented design offering unrivalled grip and comfort.

Thanks to their unique ergonomics, SPIRGRIPS® grips provide the perfect physiological contact points.

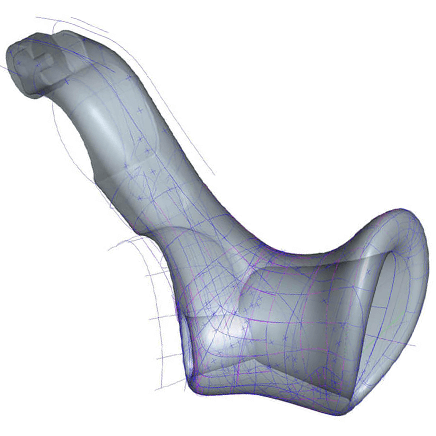

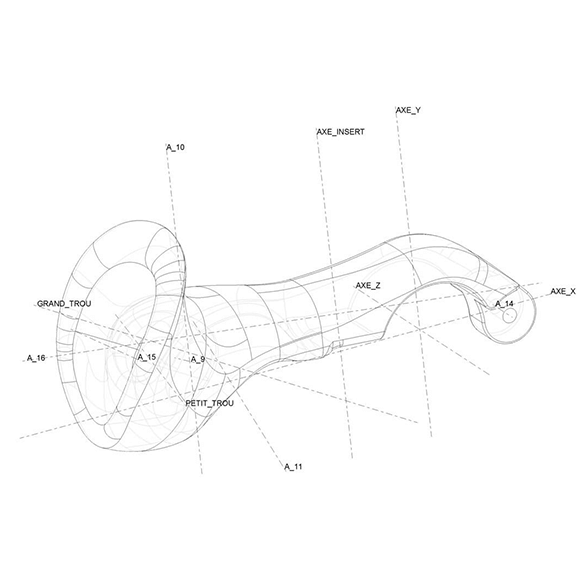

Acquisition, reconstruction and modelling

The first version of the grip was made from aluminium. After numerous tests in real conditions by competitors, a second optimised version was produced.Creation of the 3D file

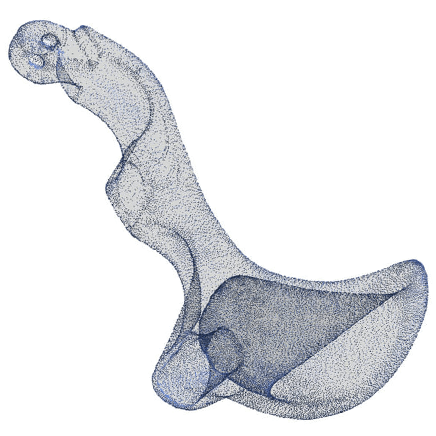

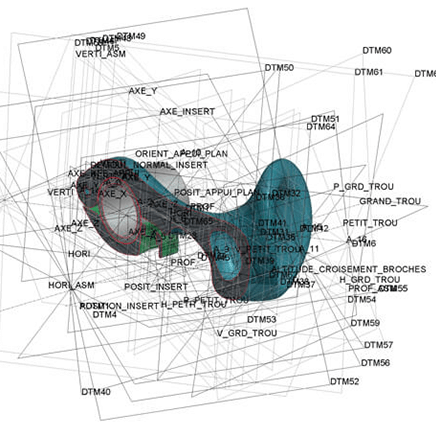

This file will form the basis for the production of prototype parts, followed by the creation of an injection mould.After the 3D scanning stage, the grip is depicted as a dense point cloud, which perfectly represents the object in terms of its overall dimensions and for defining its finest details.

Our dedicated hub enabled the new geometry to be acquired and guaranteed that the measurements were totally accurate.

This was followed by a reconstruction and modelling phase to optimise the grip.

Combining design and ergonomics for perfect on-bike integration and optimal use.

3D printing for the approval phase

- Several iterations were produced in order to approve the new grip’s ergonomics by means of user testing, as well as its perfect on-bike integration.

- With its tooling and thermoplastic injection expertise, INITIAL was able to successfully industrialise this project.

- The part is now thermoplastic injection moulded using a composite material.

SPIRGRIPS® are on sale in specialist stores.

SPIRGRIPS® grips have also been approved for use in MTB competitions by the UCI.

2 models are currently available: “Road” and “MTB”.