Polyjet 3D Printing

Multi-materials

Precision

Flexibility

Manufacturing process

Methodology

Polyjet 3D technology produces your multi-material parts thanks to its multi-jet print heads, which are fed by 4 cartridges of different materials. The layers of material are built up very quickly, and the support part is then removed by spraying with pressurized water.

Our equipment

Connex® 350 – capacity: 350 x 350 x 200 mm

Our strengths

- Professionals who listen

- Technical expertise

- Proposal-driven

Applications

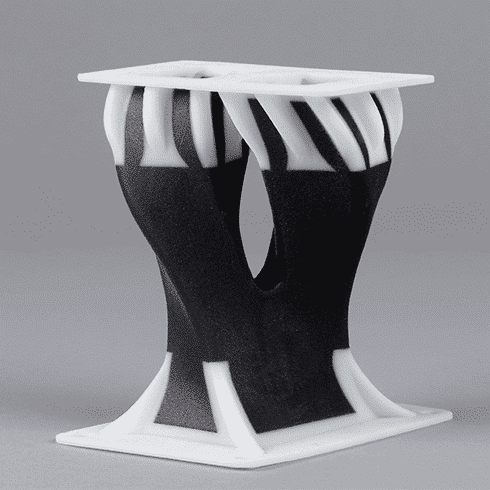

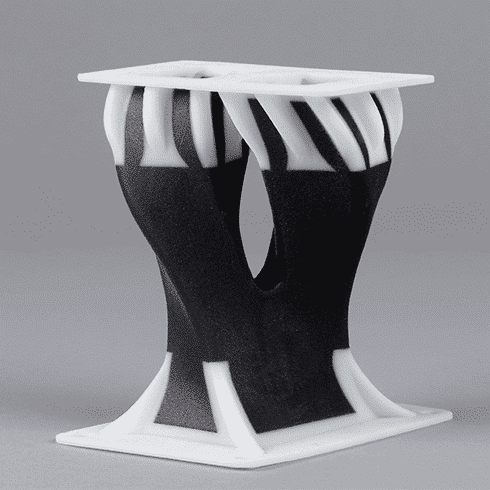

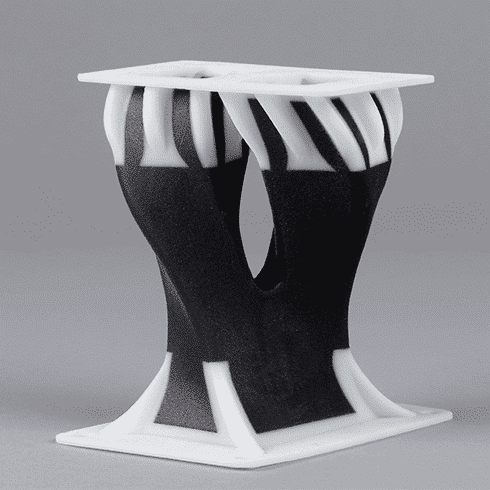

- Flexible or bi-material prototype parts

- Seals, bellows

- Shock absorbers, shoe soles, etc.

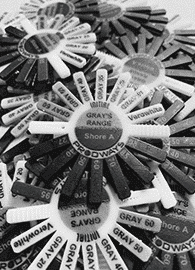

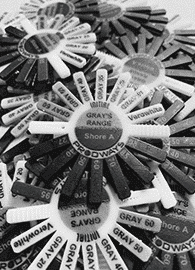

Les matériaux

- GRAY

- VEROWHITE

- TANGO BLACK PLUS®

-

GRAY

Gray: Combining dimensional stability and highly detailed visualization, this rigid opaque gray range is designed for the simulation of standard plastics and the creation of models whose appearance must match the final product.

Download the data sheetProperties- Photopolymer resin

- Rigid

- Shades of grey

Advantages- Flexural strength/tensile strength

- Wear/heat resistance

- Smooth, precise surface.

Limitations- Fragility

- Photosensitive

Accuracy- Layer: 32μ

- Recommended wall thickness: 1 mm

-

VEROWHITE

VeroWhite resin is often used to produce parts that simulate the properties and appearance of molded ABS.

Download the data sheetProperties- Photopolymer resin

- Rigid

- Opaque white

Advantages- Surface quality

- Wear resistance

- Biocompatibility

Limitations- Stiffness and strength

- Size

Accuracy- Layer: 16μ or 32μ

- Recommended wall thickness: 1 mm

-

TANGO BLACK PLUS®

Tango Black Plus is often used for the manufacture of flexible and resistant parts, such as gaskets, seals, handle covers and functional parts for electronic devices.

Download the data sheetProperties- Flexible between 27 and 95 SH A

- Black

Advantages- High resolution

- Long-lasting

Limitations- Hardness

- Heat resistance

Accuracy- Layer: 32μ

- Recommended wall thickness: 1 mm

Comparision of 3D technologies and plastics

Do you know which material is the most suitable for your high definition 3D printing project?