SLA 3D printing

Read more

Large parts

Accuracy

Appearance

Manufacturing process

Methodology

With stereolithography 3D printing, the part is reconstituted by successive layers of photosensitive epoxy resin, under the action of an ultraviolet laser. The laser beam scans the liquid resin surface according to the digital 3D model transmitted to the 3D printer. Once a layer of material has solidified, the platform is lowered by the thickness of the next layer, and a new section is solidified.

Our strengths

- Professionals who listen

- Technical expertise

- Proposal-driven

Applications

- Design validation

- Usability testing

- Marketing presentations

- Master models for vacuum casting duplication

- Mock-ups for wind tunnels

- Mass-produced parts thanks to repeatable manufacturing processes

Our equipment

- 1 x EOS® 400SX – capacity 400 x 400 x 300 mm

- 2 x 3D SYSTEMS® SLA5000 – capacity 500 x 500 x 600 mm

- 1 x Prodways DLP® L5000 – capacity 400 x 330 x 400 mm

- 3 x 3D SYSTEMS® PROX™ 800 – capacity 650 x 750 x 550 mm

Our materials

- ACCURA® 25

- 18420 PROTOGEN™

- ACCURA® CLEARVUE™

- ACCURA® XTREME™

- ULTRACUR 3280

- WATERSHED BLACK

-

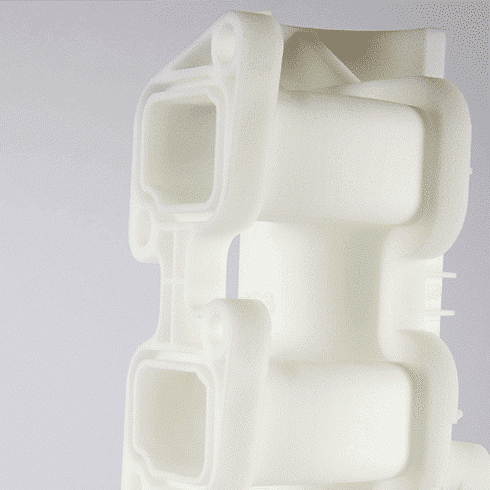

ACCURA® 25

Accura® 25 is a precise, flexible epoxy resin, ideal for assemblies and functional prototypes.

Download the data sheetProperties- Creamy white

- Flexible resin

Advantages- Very precise

- Very good surface finish

- Ideal for presentation pieces

Limitations- Thin parts.

- Max. temperature : 58°C.

Accuracy- Layer: 0.10 mm

- Recommended wall thickness: 1mm

-

18420 PROTOGEN™

ProtoGen 18420 resin is recommended for 3D printing parts requiring high precision, particularly in the medical and automotive sectors.

Download the data sheetProperties- Opaque white

- Excellent resolution and finesse.

- Biocompatible > specific cleaning procedure.

- USP Class VI.

Advantages- Highly accurate, very good surface finish.

- Ideal for display parts and master patterns for duplication.

- Temperature resistance: up to 90°C after TTH.

Limitations- Small, detailed pieces.

Accuracy- Layer: 0.15 mm

- Recommended wall thickness: 1 mm

-

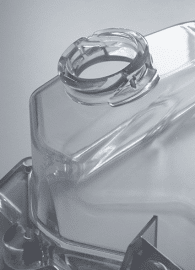

ACCURA® CLEARVUE™

Accura® Clearvue™ is a polycarbonate-type resin that offers excellent moisture resistance. It is ideal for applications requiring transparent parts.

Download the data sheetProperties- Translucent and water-resistant.

- Biocompatible > specific cleaning procedure.

- USP Class VI.

Advantages- Possibility of polishing and varnishing to obtain transparent parts.

- Large parts.

Limitations- Temperature resistance: 46°C.

Accuracy- Layer: 0.10 mm

- Recommended wall thickness: 1 mm

-

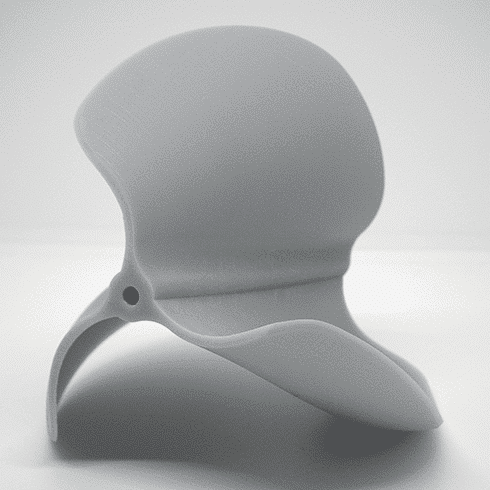

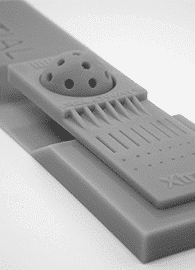

ACCURA® XTREME™

Accura® XTREME™ is an ultra-strong gray resin capable of withstanding impact and tough functional assemblies.

Download the data sheetProperties- Color: Gray

- Hard material

Advantages- Functional assemblies

- Good shock resistance

Limitations- Reduced accuracy.

- Max. temperature : 62°C

Accuracy- Layer: 0.10 mm

- Recommended wall thickness: 1mm

-

ULTRACUR 3280

ULTRACUR 3280 ceramic-filled resin boasts exceptionally high rigidity (10,000 MPa) and resistance to high temperatures.

Download the data sheetProperties- Ceramic particles

- Rigid, opaque

- Off-white, milky color

Advantages- Temperature resistance (250°C) after TTH

- Ideal for wind tunnel parts

- Easy to polish => model for electroplating

Limitations- Fragile

- Low impact resistance

Accuracy- Layer: 0.075mm – 0.10mm

- Recommended wall thickness: 2mm

-

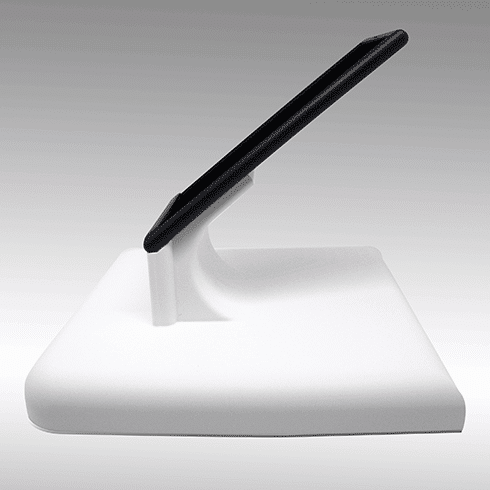

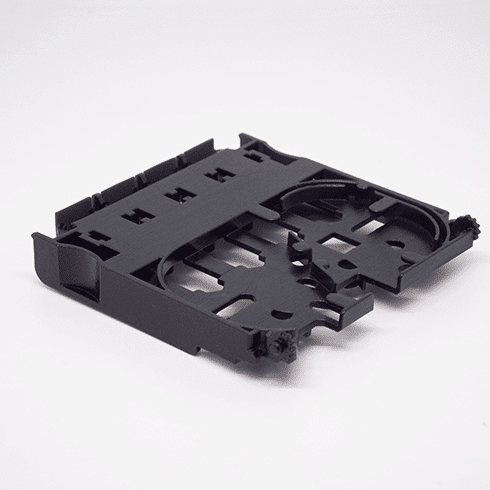

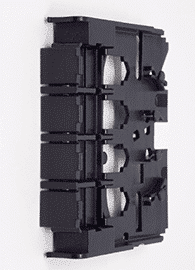

WATERSHED BLACK

Watershed Black is a resin used to produce strong, rigid parts in black. It offers superior resistance to humidity and chemicals.

Download the data sheetProperties- Color: black.

- Good mechanical and thermal characteristics.

Advantages- Black part in the mass.

- Good resistance to humidity.

Limitations- Max. temperature : 50°C.

Accuracy- Layer: 0.10mm

Comparison of 3D technologies and plastics

Do you know which material is the most suitable for your stereolithography 3D printing project?

View our comparison or why not get in touch with us.