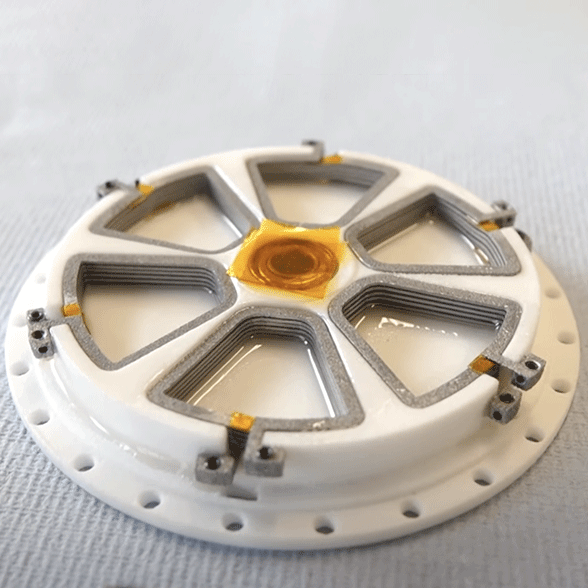

A metal 3D printed drone motor coil

[YOUR CHALLENGES//OUR CREATIONS]

THE INCREASING DEVELOPMENT OF ELECTRIC DRIVE SOLUTIONS IS VITAL FOR THE FUTURE OF THE PLANET.

Innovation resides, among other things, in the creation of an aluminium motor coil using metal Additive Manufacturing (DMLS).

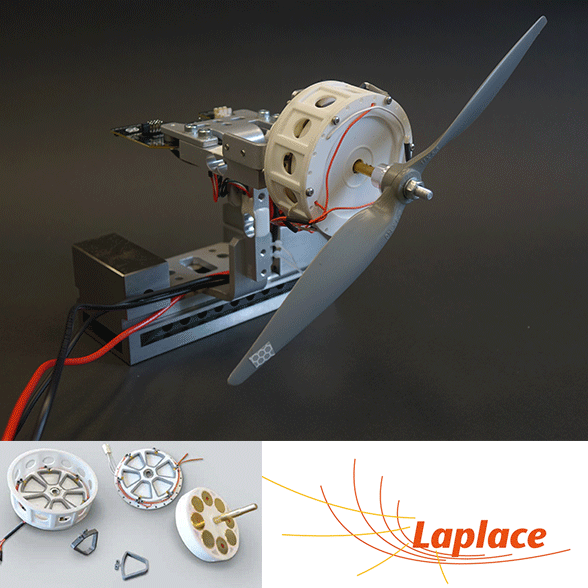

Against this backdrop, the GREM3 team, the LAPLACE Electrodynamic Research Group, developed an original brushless motor concept representing a significant evolution of the traditional electric motor, based on a brand new ironless dual-stator axial motor.

- The project took shape with the creation of a series of four prototypes, enabling the motors to be compared with each other and their actual performance to be measured.

- The weight saving is significant and we believe we can improve performance compared to a standard motor thanks to the freedom of form and design offered by 3D printing technology.

There are numerous industrial applications (drones, etc.).

ADDITIVE MANUFACTURING IN THE SERVICE OF INNOVATION

INITIAL’s support enabled tests and concept realisation to culminate in concrete measurements of the performance expected.

The key components of the motor were produced by additive manufacturing using both SLS powder sintering technology in HD PA2200 for plastic parts and metal 3D printing technology by aluminium DMLS Laser Sintering for metal parts.

Electrodynamic Research Group GREM3 – LAPLACE – CNRS – UPS – INP Toulouse

Discover the project

Entirely printed and easily replicable: a revolutionary electric drone motor

“To design a revolutionary electric drone motor, a team from the CNRS turned to INITIAL’s design office as a specialist in 3D printing for industry.”