Automotive & Mobility

SHORTER DEVELOPMENT CYCLES FOR SPEEDIER TIME TO MARKET

Lacking time to develop parts and tools?

We have the experience to implement innovative solutions to secure your supply chain.

AUTOMOTIVE 3D PRINTING

Vehicle manufacturers and their equipment makers were the first to understand the major benefits offered by automotive 3D printing.

Additive manufacturing is ideal to validate concepts, different designs and technical assemblies, enabling savings on time-to-market for vehicles, when new models are developed increasingly faster. 3D printing systems are fast becoming an integral component of production lines.

Whether using plastic injection moulding or metal, customised serial production is now possible thanks to very comprehensive equipment.

We are equipped with the best software such as Pro/Engineer, CATIA, etc. to deliver exploitable native files:

- PTC creo

- ABAQUS

- CATIA

- Solidworks

A team backed by extensive product design expertise in varied fields will assist your personnel to smooth your workload or independently analyse your systems.

We ensure discretion and efficiency to maintain confidentiality.

Our Design Office never misses a chance to use automotive 3D printing internally to speed up its processes.

We offer highly diversified equipment to assist you

We offer highly diversified equipment to assist you

in developing your parts and sub-assemblies.

Technologies such as Stereolithography, Sintered powder, FDM and

Vacuum Duplication complement each other and allow you to produce:

- Style mock-ups

- Technical validations

- Prototype series.

Functional parts and sub-assemblies will enable you to exhibit new models and new solutions to satisfy your specifications.

Using our finishing workshop you can exhibit elements comparable to serial-production products.

Automotive 3D printing is the ideal solution to present multiple styles and models without enormous investment.

Together with the know-how of a mobile, adaptable team, our high-quality equipment will save you time in defining complex forms or inspecting parts and tools.

3D scanning can save considerable time for competitive benchmarking or to integrate the style of a design mock-up into CAD.

Thermoplastic injection moulding: our workshop houses the best machines and can produce large or small series of technical parts.

- We can inject all types of polymers.

- We have an ideal site to develop tools in serial production conditions.

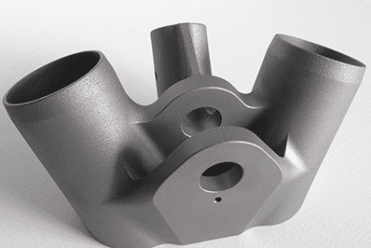

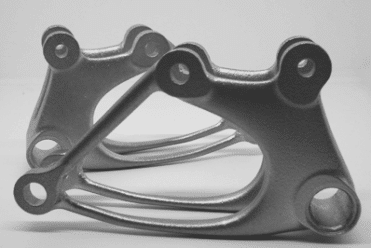

Metal 3D: a technology suited to the customisation of your special production runs.

Saving weight is the challenge of the future.

Using re-engineering, by applying the requirements of your specifications, we can design your parts using minimum materials.

Combined with additive manufacturing as an advanced production method, topology optimisation enables new minimalist design methods.