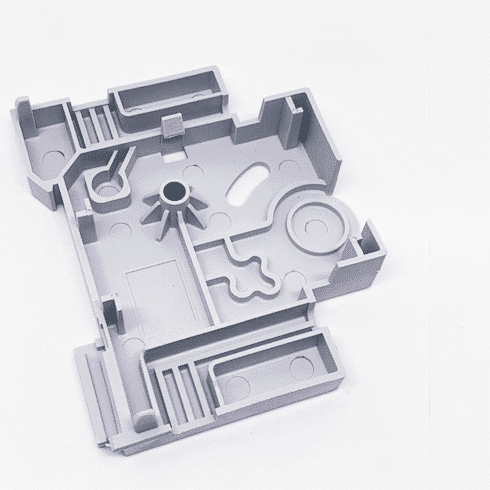

3D Molding

With 3D Molding, Initial combines 3D printing and injection molding to produce your production-grade parts. This tooling technology produced by 3D printing offers a new, responsive production method to serve your innovations. Enjoy accelerated approval and iteration processes for the development of your new products.

Read more

Read more

Prototype batch

Serves to test the properties of a product in its final material.

Rapidity

Our new responsive production mode enabling the swift development of your prototypes.

Production-grade prototype

Rapid production of almost 100 compact-size parts.

Analyse and design your parts

A unique solution

Thanks to our expertise in 3D printing and injection molding, we were ideally placed to develop this unique solution.

- We’re combining our production resources in a strategic alliance: freeing ourselves from the costs and lead times of traditional tools to gain in responsiveness.

- With 3D Moulding, Initial combines 3D printing and injection moulding to produce your production-grade parts.

During the development phase of your parts, benefit from good material prototypes in just a few days

- Validate a concept or feasibility,

- Check fit and functionality,

- Test initial solutions with users,

- or carry out tests in operating conditions.

Produce your innovations fast

This tooling technology offers you a new reactive production mode for your innovations. Benefit from accelerated validation and iteration loops for the development of your new products.

- Urgent need for parts,

- Choose a concept, a solution,

- Need the final material,

- No solution with additive manufacturing.

Accelerate the production of your injection-molded parts thanks to additive manufacturing.

This innovative alternative meets the needs of manufacturers, who can take advantage of this technological breakthrough to reduce their time-to-market.

Technical expertise

Production-grade prototype

- 3D Molding technology

-

3D Molding technology

Our 3D Molding technology lets you get your parts directly into the right material with unrivalled speed.

Control your deadlines and your budget.Download the brochureSpecifications- Imprints made using 3D printing.

- Injected thermoplastic parts.

Final material- PPGF30, ABS, ABS PC, ASA, PEBD, PC, PBT, POM, PP, PEHD, TPE, SEBS.

- FDA materials (Food Grade) : POM, PP, PEHD, TPE, SEBS.

Dimensions- Max. part size: 70 x 70 x 50 mm approx.

Production lead times- Parts delivered within 15 calendar days.

Comparison of tooling technologies

Do you know if 3D moulding is suited to producing your plastic parts?

View our comparison or why not get in touch with us.