Initial and Sauvages

The magic of animation comes to life thanks to additive manufacturing

After Ma Vie de Courgette, Claude Barras and his team are back with a moving animated film about protecting our ecosystems: Sauvages. This stop-motion animated film offered us a unique opportunity to put our CAD and additive manufacturing expertise to work on a sensitive and technically demanding work.

Despite the technical complexity of shooting a film like Sauvages, I could never imagine making it in CGI. Indeed, the path is much more important to me than the final result.

An animation challenge: Bringing characters to life

Stop motion animation is based on a simple but demanding principle: bringing inert characters to life on screen, frame by frame. This means that each character has dozens, if not hundreds, of interchangeable parts (mouths, eyelids, eyebrows, etc.) to enable an infinite number of facial expressions.

But that’s not all: beneath their expressive faces, these puppets must also be able to hold, run, fall and stand up. They therefore need a solid, articulated, precise skeleton – an invisible structure, but essential to the illusion of movement. This is where our expertise comes into play.

From scan to stage: the production stages

To meet the artistic and technical requirements of the project, our intervention took place in three main phases.

1. 3D scanning and reverse engineering

Our work began with a 3D scan of the elements sculpted by the artists. Based on these volumes, we reverse engineered the heads to generate usable CAD files. This step ensured the modularity of the various character components and the compatibility of all parts (heads, eyes, joints, etc.).

2. Design and CAD modeling of all parts

Each element – face, mouth, eyelid, skeleton – was designed and modeled taking into account mechanical constraints, interlocking, internal articulations, and of course the final aesthetic rendering. A true work of digital goldsmith.

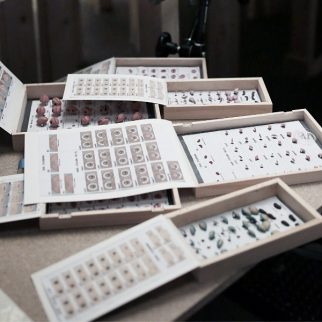

3. 2,500+ parts produced in additive manufacturing

Production was then launched in plastic and metal additive manufacturing:

- In plastic, for all the parts visible on the screen: faces, eyes, mouths (in Polyjet), eyebrows, heads and so on. This represented over 1,500 parts manufactured using various technologies (SLS, SLA).

- In metal (316L stainless steel), for the internal and articulated parts: shoulders, pelvis, hands, feet, torso, joints… a total of almost 930 precision-machined internal structural parts.

In all, over 2,500 parts were designed and produced in our workshops for this major project.

An acclaimed success

Sauvages was warmly received by critics and received several nominations (Césars, MIFA, European Film Awards ), in particular for the quality of its art direction and animation. Behind every expression, every fluid movement, lies meticulous design and manufacturing. Thanks to 3D printing, the animation teams were able to create characters that were both faithful to the artistic vision and perfectly functional. They were also highly reliable during filming and its many manipulations, making it possible to keep to a particularly demanding schedule.

A film that raises awareness of the issues facing our world

I wanted to convey the complexity of things. When you come to grips with reality, you realize that there’s much more to it than a battle between the “good guys” who want to preserve the planet and the “bad guys” who are bent on destroying it for their own gain. My aim was to go beyond a Manichean vision, by trying to respect everyone’s point of view, so as to encourage viewers to think for themselves and evolve in their apprehension of reality.

3D printing, an asset for animation

Our collaboration on Sauvages shows just how far additive manufacturing can transform production methods in the animation industry: time-saving, high precision, extensive customization and rapid iterations. When technological innovation marries artistic creativity, the result is powerful works of art.